Brand Name: PEIDE Multi Cartridge Filter System

Model Number: JLQ Multi Cartridge Filter System

Place of Origin: Jiangsu, China (Mainland)

Large flow stainless steel Multi Cartridge Filter System

Cartridge filter, also known as security filters, generally set before the pressure vessel to remove the tiny particles whose turbidity above 1 degree, to meet the requirements of the follow-up process of water; sometimes, it is also set at the end of the entire water system to prevent small particles (such as broken resin) into the finished water.

Multi Cartridge Filter System Working Principle

Cartridge filter, also known as security filter. The shell is made of high quality stainless steel, filter using molded filter, The liquid went through filter under pressure, residue left on the filter, and the filtrate outflow through the filter can effectively remove impurities in the water, sediment and suspended solids, bacteria.Molded filters are: cloth, screen, filter, sintered filter tube, wound filter, melt-blown filter, micro-porous filter and multi-function filter. Due to different filter, the filter pore size is not the same. Precision filter is between the sand filter (coarse) and a filter between ultra-filtration, filter pore size generally between 0.01-120um.For the same form of filter,it is divided into different models by their dimensions.

Commonly used wound filter and meltblown filter

Wound filter (also known as honeycomb filter), there are two types: one is polyp

ropylene fiber - polypropylene skeleton filtration, the maximum temperature 60 ℃; the other is cotton fiber - stainless steel frame filter, the maximum temperature 120 ℃.

Raw material of meltblown filter is polypropylene, the maximum operating temperature is 60 ℃. Sophisticated filters can remove suspended solids, colloidal substances and some fine particulate matter and so on.

1.Food industry:fine filter of space water, mineral water,beverages, liquor clarification and filtration process.

2. Pharmaceutical industry: sterile water, oral, infusion and injection water treatment.

3. Electronics industry: water preparation semiconductors, instruments, picture tubes and other production plants, wash water filtration bar.

4. Chemical industry: organic solvents, esters, alcohols, acids, alkalis and other chemicals, oils purification.

5. Oil industry: oil field water injection preparation and so on.

6. Environmental protection, electroplating wastewater, printing waste, pharmaceutical waste and other industrial wastewater treatment.

7. Seawater, brackish water desalination water treatment, hotels, apartments water treatment.

8. Precision filter is often used as security filter for electrodialysis, ion exchange, security filters reverse osmosis devices.

Parameter of 316 cartridge water filter

| Working pressure: | 0.6 / 1.0 / 1.6Mpa |

| Body Material: | Stainless steel (SUS304, SUS304L, SUS316, SUS316L). |

| Operating temperature: | 5 ~ 40 ℃ (exceed 60 ℃ to be informed) |

| Design temperature: | 5 ℃ -100 ℃ |

| Replace the pressure: | 0.05Mpa-0.07MPA |

| Filter interface: | flat compression, plug-in |

| Cylinder and base connection mode: | quick opening, flanged |

| Filtration accuracy: | 1μm ~ 100μm |

| Cartridge Quantity: | 1 core to 180 cores |

| Filter Length: | 10 "~ 40" |

| Seal type: | O-ring or flat washer |

| Seal Material: | PTFE, rubber. |

| Outside treating : | matte jet beads, mirror electrolytic polishing. |

| Sealing material: | nitrile rubber, silicone, Viton, standard configuration for the silicone seal. |

| Interface Type: | GB, HG, DIN, ANSI, JIS standard flanges, dental mouth, clamps and so on. |

| Flange Standard: | GB, HG, SH, HGJ, JB, ANSL, JIS and other standards. (User-specified, please indicate the pressure level) |

| Manufacturing, testing standard: | GB150 standard, or user-specified criteria. |

Material of filter |

Temperature(℃) |

Pressure(Mpa) |

Precision(μm) |

Size(mm) |

Sintered titanium alloy filter |

≤300 |

0.015 |

0.3~100 |

Φ50×120 Φ50×450 Φ60×110 Φ60×300 Φ60×500 Φ60×1000 |

Stainless plait filter |

≤500 |

0.01 |

2~180 |

Φ35×210 Φ65×250 Φ86×350 Φ86×500 Φ90×1000 |

PTFE plait filter |

≤140 |

0.011 |

0.02~50 |

Φ45×250 Φ45×500 Φ45×1000 Φ60×250 Φ60×500 Φ60×1000 |

PP plait filter |

≤60 |

0.012 |

0.1~60 |

Φ45×250 Φ45×500 Φ45×1000 Φ60×250 Φ60×500 Φ60×1000 |

Metal fiber sintered felt |

≤130 |

0.01 |

1~70 |

Φ180×425 Φ180×800 Φ180×1000 |

Ceramic filter |

≤250 |

0.018 |

0.4~80 |

Φ100×300 |

Melt-down filter |

≤60℃ |

0.015 |

1-100 |

Φ60×250 Φ60×500 Φ60×750 Φ60×1000 |

Wound filter |

≤60℃ |

0.012 |

1-100 |

Φ60×250 Φ60×500 Φ60×750 Φ60×1000 |

Multi Cartridge Filter System Characteristics

1.High filtration precision, uniform pore size filter.

2.Small filtration resistance, flux, interception capability, long service life.

3.Filter is clean and no second pollution to the filter media.

4.It also can filter acid, alkali and other chemical agents.

5.High-intensity,heat-resistant,deformation resistance.

6.Low price, low running costs, easy to clean, filter can be replaced.

Multi Cartridge Filter System Composition

Cartridge filter is mainly composed by the filter housings, filter cartridges and other components, and the filter housings materials is mostly made of R304 stainless steel, if it’s used in the acid and other special occasions,it will be made by R316 stainless steel. It an be divided into the flange and clamp, and flanged housing is mainly used in the occasion of larger flow filtration. The filter is mainly made by PP cotton, it can also be made by wound filter or activated carbon filter on some occasions. The number of filter may vary from 1 to dozens, primarily be determined from the water flow rate.

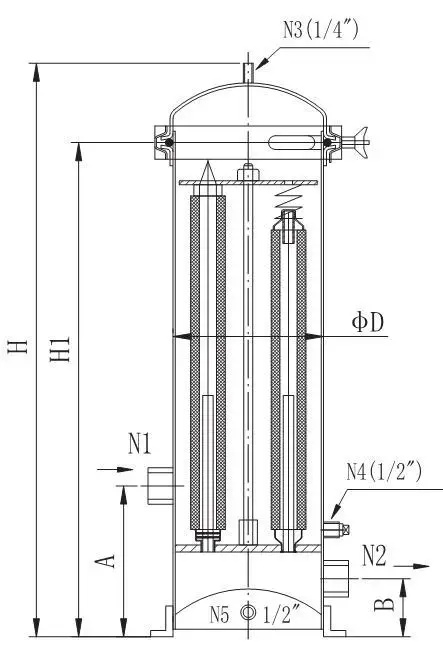

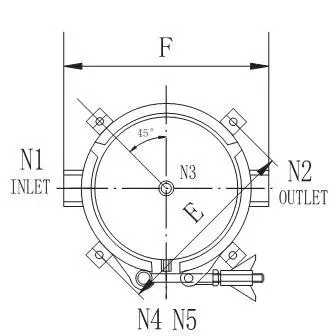

Small-flow Multi Cartridge Filter System with clampopening.

1. The body open the way for quick opening hoop (or quick opening flange), to facilitate the efficient filter replacement and cleaning.

2. Compact structure, small size, improved V-shaped hoop quick opening, the stress tests, the pressure without any distortion and leakage after 0.6MPA.

3. Cartridge filter uses stainless steel as material,with electrochemical polishing or matte finishing out appearance. Also PP is available.

Multi Cartridge Filter System Parameter- Small Flow Rate with hoop cover

| Model | ΦD | A (mm) | B(mm) | H(mm) | N1/N2Φ | (m³/H) |

| JLQ1-10" | Φ 108 | 90 | 45 | 380 | 1" | 0.5 |

| JLQ1-20" | Φ 108 | 90 | 45 | 650 | 1" | 1 |

| JLQ3-10" | Φ 160 | 120 | 245 | 500 | 1" | 1.5 |

| JLQ1-20" | Φ 160 | 120 | 45 | 700 | 1" | 3 |

| JLQ5-10" | Φ 200 | 120 | 45 | 500 | 1.5" | 2.5 |

| JLQ-5-20" | Φ 200 | 120 | 45 | 740 | 1.5" | 5 |

| JLQ5-30" | Φ 200 | 160 | 60 | 1010 | 2" | 7.5 |

| JLQ5-40" | Φ 200 | 160 | 60 | 1290 | 2" | 10 |

| JLQ7-10" | Φ 230 | 160 | 60 | 500 | 1.5" | 7 |

| JLQ7-20" | Φ 230 | 160 | 60 | 760 | 1.5" | 7 |

| JLQ7-30" | Φ 230 | 160 | 60 | 1030 | 2" | 10.5 |

| JLQ7-40" | Φ 230 | 160 | 160 | 1310 | 2" | 14 |

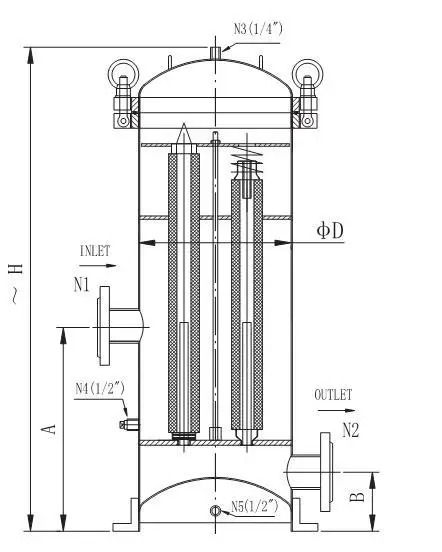

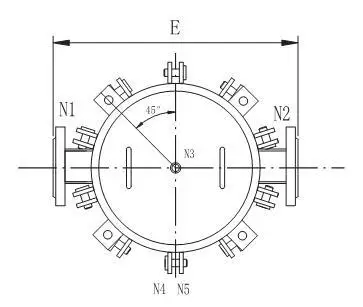

Multi Cartridge Filter System -Small Flow Rate with flange cover

Multi Cartridge Filter System Parameter- Small Flow Rate with flange cover